How Vancouver Contractors Save Time With Advanced Robotic Pipeline Cutting Technology

Vancouver contractors are increasingly adopting advanced robotic pipeline cutting technology to optimize their construction processes. This innovation enables faster, more precise cutting, reducing manual labor and project timelines. As contractors embrace this change, they experience significant benefits in efficiency and quality. However, the implications of this shift extend beyond immediate gains, raising questions about the future of construction in the region. What does this mean for the industry moving forward?

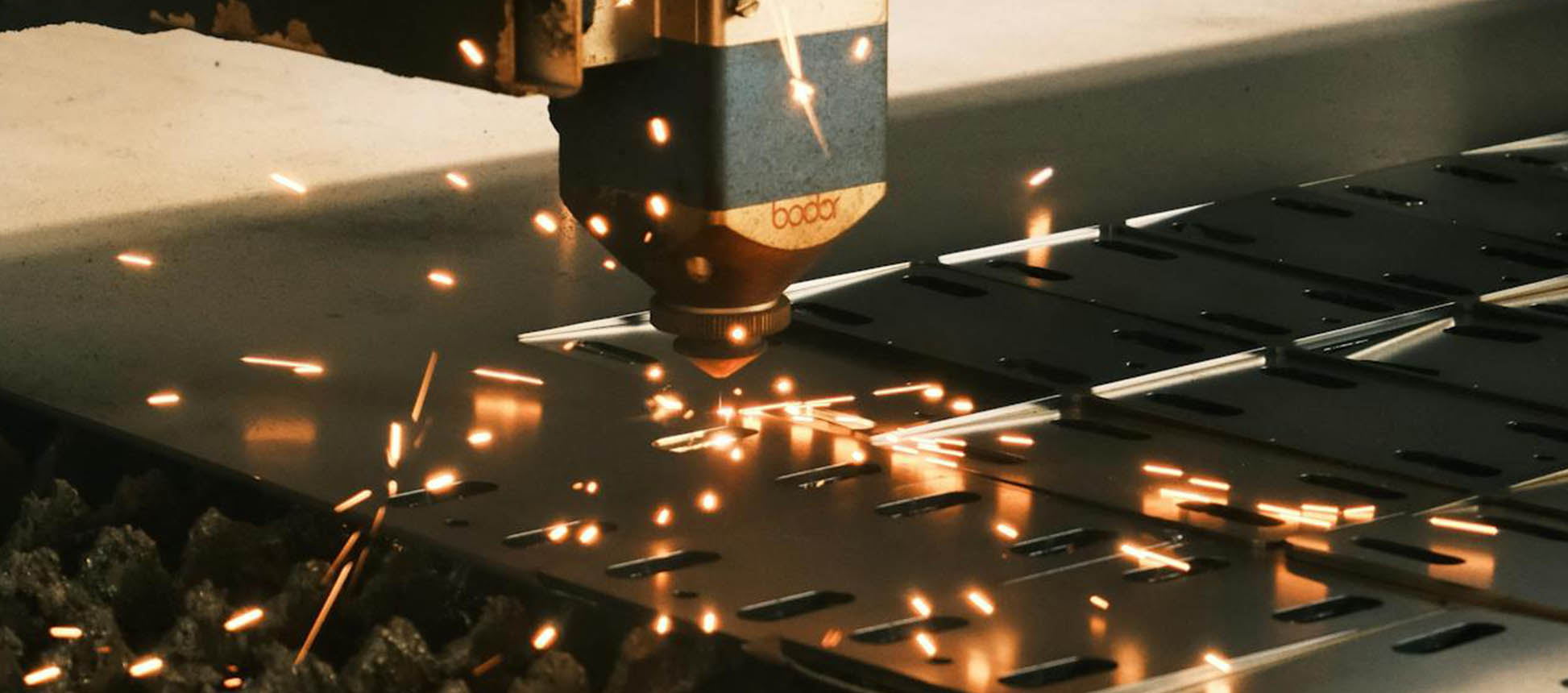

The Rise Of Robotics In Construction

As the construction industry faces increasing demands for efficiency and precision, the integration of robotics has emerged as a transformative solution. Robotic innovations are reshaping traditional practices, enabling contractors to adopt construction automation that enhances productivity and reduces human error. With the ability to perform repetitive tasks with high accuracy, robots have become essential at every stage of construction, from site preparation to assembly.

These advancements not only streamline workflows but also help in addressing labor shortages, allowing companies to meet project deadlines more effectively. The rise of robotics also encourages the development of safer work environments, as machines take on hazardous tasks that would otherwise put human workers at risk. As contractors in Vancouver and beyond explore the potential of robotic technologies, the construction landscape continues to evolve, setting new standards for efficiency and reliability.

Benefits Of Robotic Pipeline Cutting

Robotic pipeline cutting technology offers a range of advantages that align with the industry's shift towards automation. One significant benefit is increased cutting efficiency, reducing the time contractors spend on tasks. This efficiency not only accelerates project timelines but also minimizes labor costs. Additionally, these robotic innovations enhance worker safety by limiting their exposure to hazardous environments, as machines can perform challenging cuts in tight or dangerous spaces. The precision of robotic systems also reduces material waste, contributing to more sustainable construction practices. Furthermore, advances in pipeline technology enable contractors to tackle complex projects that may have previously been deemed too difficult or time-consuming. As the construction industry continues to embrace automation, the integration of robotic pipeline cutting is likely to become standard practice, driving further improvements in productivity and safety across projects.

Enhanced Precision And Accuracy

Enhanced precision and accuracy in pipeline cutting revolutionize the construction process, allowing contractors to achieve tighter tolerances and more intricate designs. The integration of advanced robotic technology enhances precision engineering by utilizing sophisticated algorithms and sensors that ensure each cut is executed with remarkable exactness. This level of measurement accuracy minimizes human error and eliminates the need for extensive rework, resulting in superior quality in the final product. Contractors benefit from the ability to create complex geometries and unique piping configurations that were previously challenging to achieve manually. Furthermore, the consistency provided by robotic systems ensures that each cut meets the stringent standards required for various construction projects. As Vancouver contractors embrace this technology, they are not only improving their craftsmanship but also pushing the boundaries of what is possible in pipeline construction. The focus on enhanced precision and accuracy ultimately transforms project outcomes and elevates industry standards.

Time Efficiency And Project Timelines

The implementation of robotic pipeline cutting technology significantly impacts time efficiency and project timelines in construction. By automating cutting, contractors can streamline operations, reducing the time spent on manual tasks. This advancement allows for enhanced workflow optimization, where each phase of the project can be executed with greater speed and precision.

Robotic systems can perform complex cuts in a fraction of the time it would take traditional methods, leading to more accurate project scheduling. As a result, contractors can adhere to deadlines more effectively, minimizing delays that might arise from labor-intensive processes.

Moreover, the ability to program robotic machines for specific tasks ensures that projects remain on track, allowing for better resource allocation. Ultimately, integrating this technology not only accelerates job completion but also contributes to a more organized, efficient construction environment, setting new standards for time management in the industry.

Cost Savings And Reduced Labor Needs

Cost efficiency becomes a significant advantage with the adoption of robotic pipeline cutting technology in construction. By automating cutting, contractors can significantly reduce labor costs. Traditional methods often require multiple workers to handle intricate tasks, resulting in inflated project costs. In contrast, robotic technology streamlines operations, enabling a single operator to oversee the machinery, thereby minimizing the need for extensive labor teams.

Additionally, the precision of robotic cutting reduces material waste, further enhancing overall project budgeting. With less rework needed due to improved accuracy, contractors can allocate resources more effectively and predict costs with greater reliability. This financial predictability enables better planning and management of project budgets, ensuring funds are used efficiently. As a result, Vancouver contractors are increasingly recognizing the potential for substantial cost savings and reduced labor needs through the integration of advanced robotic solutions into their construction processes.

Safety Improvements In Construction Sites

Robotic pipeline cutting technology significantly enhances safety on construction sites by minimizing potential hazards associated with manual cutting processes. Traditional cutting methods often expose workers to risks such as injuries from sharp tools and falling debris. By automating these tasks, the technology reduces the need for workers to be in proximity to dangerous equipment.

Furthermore, robotic systems can conduct site inspections more efficiently, allowing for real-time monitoring of the work environment. This capability enables contractors to identify hazards before they pose risks to worker safety. Enhanced surveillance and precision in cutting also contribute to fewer accidents and a more controlled work environment.

The implementation of robotic cutting technology not only streamlines operations but also underscores a commitment to prioritizing worker safety. By adopting such advancements, construction sites can achieve higher safety standards, ensuring that the well-being of workers remains paramount throughout the project lifecycle.

Environmental Impact And Waste Reduction

While construction projects often contribute to environmental degradation, the adoption of robotic pipeline cutting technology presents a compelling opportunity for waste reduction and ecological preservation. This innovative approach minimizes material waste through precise cutting techniques, enabling more efficient resource management. By reducing excess scrap and optimizing material use, contractors can significantly lower their environmental footprint.

Moreover, robotic technology aligns with sustainable practices that many Vancouver contractors are increasingly prioritizing. The automation of pipeline cutting not only enhances accuracy but also decreases the need for heavy machinery, which can contribute to noise and air pollution. By streamlining operations and minimizing waste, contractors can adhere to stricter environmental regulations while promoting a greener construction culture. As a result, the incorporation of robotic technology not only benefits project timelines but also advances the industry's commitment to sustainability and responsible resource management.

Future Trends In Robotic Technology For Contractors

As the construction industry continues to evolve, the integration of advanced technologies is set to transform contractor operations significantly. Future trends in robotic technology indicate an increased reliance on artificial intelligence and machine learning, enabling contractors to optimize project efficiency and accuracy. Robotics will likely incorporate AI algorithms that analyze vast amounts of data to predict maintenance needs and streamline workflows.

Moreover, machine learning will enhance robotic systems' ability to adapt to various construction environments, allowing for more precise cutting and assembly tasks. These advancements are expected to reduce human error, minimize safety risks, and improve overall project timelines.

Additionally, the use of collaborative robots, or cobots, will facilitate seamless interactions between human workers and machinery, further enhancing productivity. The future promises a construction landscape where robotic technology, powered by AI and machine learning, will redefine how contractors approach their projects, leading to smarter and more efficient operations. If you are searching for "robotic pipeline cutting company near me" online, be sure to check out Sarkinen Industrial Pipelining.

Contact A Robotic Pipeline Cutting Company In Vancouver, WA

Advanced robotic pipeline cutting technology is revolutionizing the way Vancouver contractors approach repair and maintenance projects. By minimizing manual labor and maximizing precision, these innovative systems allow teams to complete complex tasks in a fraction of the time—without compromising quality or safety. Whether it’s for residential, commercial, or industrial projects, the benefits of robotic solutions are clear: faster turnaround, reduced downtime, and more efficient operations.

Take your next project to the next level—contact Sarkinen Industrial Pipelining, a professional robotic pipeline cutting company in Vancouver, WA, today and discover how automation can save you time, money, and effort.